UV inspection lights are handy tools that help you spot things you can’t see with regular light. These special lights use ultraviolet (UV) rays to make certain materials glow or shine. You might use them to check for stains, cracks, or other flaws in products.

UV inspection lights come in different types and sizes to fit various jobs. Some are small like flashlights, while others are bigger for checking larger areas. They’re used in many fields, from making sure products are good quality to looking for hidden marks on money.

These lights work by shining UV rays on objects. Some things react to UV light by glowing brightly. This makes it easy to see stuff that’s hard to spot otherwise. UV lights are great for finding tiny problems or hidden details in all sorts of items.

Understanding UV Inspection Lights

UV inspection lights are special tools that help find hidden problems in many things. They use a type of light our eyes can’t see to make certain materials glow. This makes it easier to spot flaws, cracks, and other issues that might be hard to notice otherwise.

Basics of UV Light

UV light is a kind of energy that’s invisible to us. It has shorter waves than the light we can see. When UV light hits some materials, it makes them shine brightly. This is called fluorescence. UV inspection lights use this trick to help you find things that are hard to see normally.

There are different types of UV light. The one used most for inspections is called UV-A. It’s the safest type and works well for many jobs. UV light can show you tiny cracks, leftover cleaning fluids, and even some bugs!

Types of UV Inspection Lights

You can choose from several kinds of UV inspection lights:

- Mercury vapor lamps: These are strong and have been used for a long time. They take a while to warm up but give off a lot of UV light.

- LED lamps: These are newer and becoming more popular. They turn on right away and don’t use much power. They’re also smaller, which makes them easy to carry around.

- UV-A inspection lamps: These are made just for looking at things up close. They come in different shapes and sizes to fit various jobs.

Some UV lights can switch between regular light and UV light. This helps you find the spot you want to check before turning on the UV. Remember to wear safety glasses when using UV lights to protect your eyes.

Applications of UV Inspection Lights

UV inspection lights have many uses in industry and quality control. They help find hidden flaws and check for cleanliness in ways normal lights can’t.

Industrial Non-Destructive Testing

UV lights are key tools for non-destructive testing in factories. They can spot tiny cracks or flaws in metal parts without damaging them. This is great for checking airplane parts or car engines.

You can use UV lights to inspect welds too. The light makes small defects glow, so you can see them easily. This helps keep products safe and high-quality.

Some UV inspections use special dyes. You spray the dye on a part, then shine the UV light. Any cracks will light up bright!

Verification of Cleanliness and Contamination

UV lights are super helpful for checking if things are really clean. Many oils and fluids glow under UV light. This makes it easy to spot leftovers after cleaning.

In food factories, UV lights can find bits of food stuck in machines. This helps keep everything spotless and safe.

You can also use UV lights to check for leaks. Some UV dyes are added to fluids like oil or coolant. If there’s a leak, the UV light will make it glow.

In labs, UV lights help spot contamination on surfaces. This is key for keeping work areas clean and experiments accurate.

The Role of UV Lights in Inspection Techniques

UV lights play a key part in finding hidden flaws in many types of parts and materials. They help make tiny cracks and defects glow so you can spot them easily.

Magnetic Particle Inspection (MPI)

In MPI, UV lights are your secret weapon for finding surface and near-surface flaws in metal parts. Here’s how it works:

- You apply magnetic particles to the part

- You magnetize the part

- You shine a UV light on it

The UV light makes the particles glow bright green or yellow. This helps you see where they’ve gathered around tiny cracks or flaws.

MPI is great for checking welds, forgings, and other metal parts. You can use it on big stuff like train axles or small things like bolts.

Some key MPI tools include:

- Magnaflux machines

- UV lamps (black lights)

- Fluorescent magnetic particles

MPI lets you find flaws you can’t see with just your eyes. It’s fast, easy to use, and doesn’t harm the part you’re testing.

Safety Considerations When Using UV Lights

UV lights can be harmful if not used properly. Always wear UV-blocking goggles to protect your eyes. These special glasses shield your eyes from damage.

Cover exposed skin with long sleeves, pants, and gloves. UV rays can burn your skin quickly, even if you don’t feel it right away.

Keep others away from the area when using UV lights. Put up warning signs to let people know UV light is in use.

Turn off UV lamps when not needed. Don’t leave them on for more than 15 minutes at a time. This helps prevent accidental exposure.

Check your UV equipment regularly for damage or wear. Replace bulbs and other parts as needed to ensure safe operation.

Be careful around reflective surfaces. UV light can bounce off shiny objects and cause indirect exposure.

Store UV lights safely when not in use. Keep them out of reach of children and pets.

If you feel eye pain or skin irritation after using UV lights, see a doctor right away. Quick treatment can prevent lasting damage.

Events and Developments in UV Inspection Technology

UV inspection lights have come a long way in recent years. You might be surprised by how much they’ve improved!

LED technology has made UV lights cheaper and more energy-efficient. Just a few years ago, UV LEDs cost around $30 each. Now you can get them for under $5.

Sensors for UV inspection have gotten much better too. They’re faster, more precise, and work from farther away than before.

Some cool new uses for UV inspection have popped up. In medical fields, UV lights help check if equipment is clean. Car makers use them to spot tiny flaws in paint jobs.

UV lights are handy for checking glue seams in packaging. They make sure the glue goes all the way around without gaps.

Safety is always important with UV light. New protective glasses and clothing keep workers safe while using stronger UV sources.

Selecting the Right UV Inspection Light

The right wavelength, brightness, size, and battery life can make a big difference in how well you can spot flaws or issues.

Wavelength and Intensity

UV inspection lights work best at specific wavelengths. For most industrial uses, you’ll want a light that puts out UV-A rays at 365 nanometers. This wavelength makes fluorescent materials glow brightly.

The brightness of the light matters too. Look for lights with high intensity, measured in microwatts per square centimeter (µW/cm²). Brighter lights help you see tiny flaws more easily.

Some lights come with filters to block out visible light. This can help you see fluorescent materials more clearly against dark backgrounds.

Portability and Battery Life

For on-the-go inspections, you’ll want a light that’s easy to carry. Hand-held LED UV lamps are popular because they’re lightweight and tough.

Battery life is crucial for longer jobs. Look for lights that can run for several hours on a single charge. Some models offer replaceable batteries, which can be handy for all-day use.

Many portable lights now use LED bulbs. These last longer and use less power than older-style UV lamps. They also turn on instantly, with no warm-up time needed.

Introducing MFOPTO UV Inspection Light

MFOpto UV Inspection Light stands out as a premium choice for professionals. It is exceptionally effective for detecting leaks in systems such as HVAC and revealing fluorescent substances.

Key Features:

- High-Intensity UV Light: The powerful UV-A beam ensures thorough inspections with unmatched precision.

- Compact & Portable Design: Lightweight and easy to carry, the MFOpto light fits perfectly in pockets or tool bags. Convenient for on-the-go inspections.

- Multifunctional Use: Ideal for various applications, from industrial inspections to routine maintenance checks.

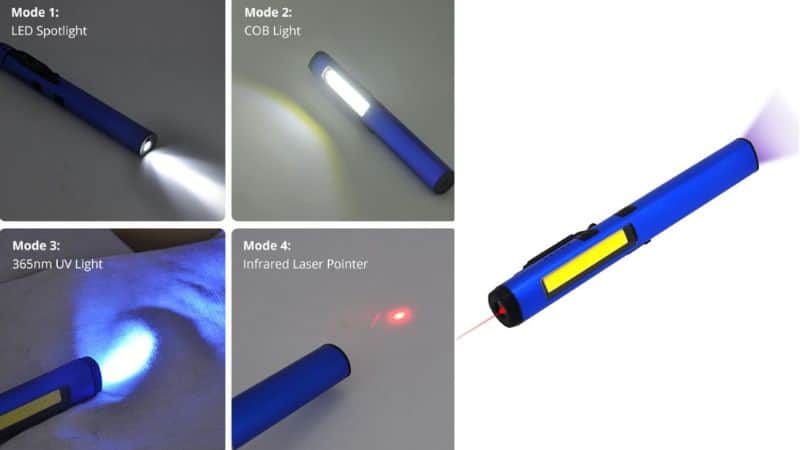

- 4 Operation Modes: LED Torch Bright / COB Worklight Bright / UV LED Bright / Red Laser Point

To learn more about the specific models and features available, Contact Us today and request a detailed product catalog or consultation. We’re happy to answer your questions and help you find the ideal UV inspection light for your needs.