LEDs have revolutionized modern lighting, with SMD (Surface Mounted Device) and COB (Chip On Board) technologies leading the way. These two types of LEDs offer unique advantages for various lighting applications, from homes to industrial spaces. Understanding the differences between SMD and COB LEDs is crucial for both homeowners and lighting professionals to make informed decisions.

This blog will explain the key differences, benefits, and ideal use cases for SMD and COB LEDs, enabling you to choose the right option for your specific lighting needs. By the end, you’ll have a clear grasp of these technologies and their practical applications.

Overview of SMD LED

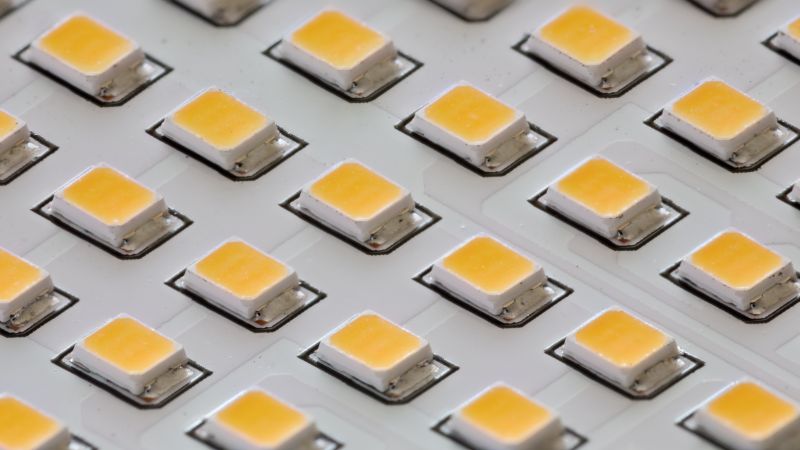

What Are SMD LEDs?

SMD stands for Surface Mounted Device, a technology where LED chips are mounted directly onto the surface of a circuit board. Unlike traditional LEDs, SMD LEDs are compact, allowing multiple chips to be placed closely together. This configuration enables greater flexibility in design and application.

Popular Variants and Sizes

SMD LEDs come in various sizes and configurations, each suited for different purposes. Common variants include:

- 2835: Measures 2.8mm x 3.5mm, offering high efficiency and brightness. Ideal for general lighting and backlighting applications.

- 5050: Larger at 5.0mm x 5.0mm, containing three separate diodes within a single package. Perfect for vibrant color displays and creative lighting designs.

Common Applications

SMD LEDs are versatile and widely used in various applications, such as:

- General Lighting: Suitable for residential and commercial lighting due to their energy efficiency and flexibility.

- Backlighting: Commonly used in televisions, monitors, and smartphone screens to provide uniform illumination.

- Decorative Lighting: Ideal for creating dynamic and colorful lighting effects in both indoor and outdoor settings.

Overview of COB LED

What Are COB LEDs?

COB stands for Chip On Board, a technology where multiple LED chips are packaged together as a single module directly on the circuit board. This design allows for a higher density of LEDs, resulting in increased brightness and efficiency.

How COB Technology Operates

In COB LEDs, numerous tiny LED chips are mounted closely together on a substrate, creating a single, large light-emitting surface. This configuration enhances light output and ensures uniform illumination without the visible dots often seen in SMD LEDs.

Common Applications

COB LEDs are favored in applications requiring high brightness and efficient heat dissipation, including:

- High-Brightness Lighting: Ideal for industrial lighting, streetlights, and floodlights where intense illumination is necessary.

- Outdoor Lighting: Perfect for gardens, patios, and commercial outdoor spaces due to their robust performance and durability.

- Spotlighting: Used in retail displays and architectural lighting to highlight specific areas with precision.

Key Differences Between SMD and COB LEDs

Understanding the fundamental differences between SMD and COB LEDs is essential for selecting the right lighting solution. Here, we compare them across several critical aspects:

Brightness and Lumens

- COB LEDs: Generally produce higher lumen output due to the close placement of multiple chips, making them significantly brighter than SMD LEDs.

- SMD LEDs: While bright, they may require more units to achieve the same brightness level as COB LEDs.

Energy Efficiency

- SMD LEDs: Typically more energy-efficient per watt, making them a cost-effective choice for applications where energy consumption is a primary concern.

- COB LEDs: Though slightly less efficient per watt compared to SMDs, their higher brightness can offset energy consumption in high-intensity applications.

Heat Dissipation

- COB LEDs: Superior heat management owing to their design, which allows for better heat distribution and longer lifespan.

- SMD LEDs: Manage heat effectively but may not perform as well as COB LEDs in high-temperature environments.

Light Distribution

- COB LEDs: Offer smoother and more uniform light distribution, eliminating the “spotty” effect seen in SMD LEDs.

- SMD LEDs: Provide versatile light distribution with the ability to create dynamic lighting effects but may require multiple units for uniform illumination.

Pros and Cons of SMD LEDs

Advantages |

Higher Energy Efficiency: Consumes less power for adequate brightness, reducing electricity costs. |

| Flexible Use: Versatile in design, allowing for a wide range of applications from decorative to functional lighting. | |

| Easier Replacements: Modular design makes it simpler to replace individual LEDs without affecting the entire system. | |

Disadvantages |

Less Brightness Compared to COB: May require more units to achieve the desired brightness level, potentially increasing installation costs. |

| Potential for Visible LED Points: In certain applications, the individual LED points may be visible, affecting the aesthetic quality of the lighting. |

Pros and Cons of COB LEDs

Advantages |

Higher Brightness Levels: Delivers intense illumination suitable for large spaces and high-intensity applications. |

| lexible Use: Versatile in design, allowing for a wide range of applications from decorative to functional lighting. | |

| Fewer Components Needed: Simplifies installation by reducing the number of separate units required for high brightness. | |

Disadvantages |

Higher Manufacturing Costs: The advanced technology and higher density of LEDs contribute to increased production costs. |

| Potentially More Heat Generation: Although COB LEDs have better heat dissipation, the concentrated light can still generate significant heat, necessitating effective cooling solutions. |

Cost Considerations

When choosing between SMD and COB LEDs, it’s essential to consider both initial and long-term costs:

- SMD LEDs: Generally have a lower initial cost due to simpler manufacturing processes. Their higher energy efficiency can lead to long-term savings on electricity bills.

- COB LEDs: Higher upfront costs reflect their superior brightness and advanced technology. However, their longevity and reduced maintenance needs can result in cost savings over time.

Choosing the Right LED for Your Needs

Factors to Consider

- Application: Determine whether you need broad, general illumination or focused, high-intensity lighting.

- Required Brightness: Assess the lumen output necessary for your space. COB LEDs are preferable for higher brightness needs.

- Cost: Weigh the initial investment against long-term savings. SMD LEDs may be more budget-friendly upfront.

- Energy Efficiency: Consider how important energy consumption is for your application. SMD LEDs typically offer better efficiency per watt.

Real-World Examples

- Residential Lighting: SMD LEDs are ideal for home lighting due to their flexibility and energy efficiency.

- Commercial Lighting: COB LEDs excel in office spaces and retail environments that require bright, uniform lighting.

- Outdoor Lighting: COB LEDs are perfect for streetlights and garden lighting where high brightness and durability are essential.

Both SMD and COB LEDs offer unique advantages tailored to different lighting needs. SMD LEDs provide flexibility, energy efficiency, and ease of replacement, making them suitable for a wide range of applications from residential to commercial use. On the other hand, COB LEDs deliver superior brightness, uniform light distribution, and better heat management, making them ideal for high-intensity and outdoor lighting solutions.

By understanding the key differences and benefits of SMD and COB LED technologies, you can make informed decisions that enhance the effectiveness, efficiency, and aesthetics of your lighting setups.

Looking for an SMD & COB Flashlight Manufacturer?

If you’re in search of reliable SMD and COB flashlight manufacturers, consider MF Optoelectronics. We specialize in high-quality LED lighting solutions and offer a range of products to meet your specific needs. Explore our website for more information.

FAQs:

Q1: Can COB and SMD LEDs be used together in the same lighting system?

A1: Yes, SMD and COB LEDs can be integrated into the same lighting system, provided that the fixtures and electrical components are compatible. This approach allows for a combination of high-brightness illumination and flexible, dynamic lighting effects. However, careful planning is required to manage heat dissipation and ensure optimal performance of both LED types.

Q2: Which LED type has a longer lifespan? SMD or COB?

A2: Both SMD and COB LEDs boast long lifespans, often exceeding 50,00050,000 hours of operation. The actual lifespan can depend on factors such as heat management, quality of the LEDs, and operating conditions. COB LEDs may have a slight edge in lifespan due to their superior thermal management, but both technologies are designed for durability and longevity.

Q3: Are COB LEDs compatible with standard LED drivers?

A3: COB LEDs typically require compatible LED drivers that can handle their specific voltage and current requirements. It’s essential to use drivers that match the electrical specifications of the COB modules to ensure safe and efficient operation. Always consult the manufacturer’s guidelines when selecting drivers for COB LEDs.

Q4: How do SMD LEDs perform in extreme weather conditions compared to COB LEDs?

A4: Both SMD and COB LEDs can be designed to withstand extreme weather conditions when properly encapsulated and constructed. However, COB LEDs, with their integrated chip design and enhanced thermal management, may offer better performance in harsh environments. Ensuring proper IP (Ingress Protection) ratings and using weather-resistant fixtures is crucial for optimal performance of either LED type outdoors.

Q5: Can I retrofit my existing lighting fixtures with COB LEDs?

A5: Retrofitting existing fixtures with COB LEDs is possible but may require modifications to accommodate the different form factors and heat management needs of COB modules. It’s important to assess the compatibility of your current fixtures with COB LEDs and consult with a lighting professional to ensure a seamless and safe installation.

Q6: How do SMD and COB LEDs compare in terms of environmental impact?

A6: Both SMD and COB LEDs are environmentally friendly compared to traditional lighting options, as they consume less energy and have longer lifespans, reducing waste and energy consumption. The production processes for both types involve the use of semiconductor materials, but advancements in manufacturing are continually improving their sustainability. Proper recycling and disposal of LED fixtures also contribute to minimizing their environmental footprint.

Q7: What maintenance is required for SMD and COB LED lighting systems?

A7: LED lighting systems, including both SMD and COB types, generally require minimal maintenance due to their durability and long lifespans. Regular cleaning to remove dust and debris can help maintain optimal light output and heat dissipation. For COB LEDs, ensuring that heat sinks remain free of obstructions is important for thermal management. SMD LEDs may need occasional replacement of individual modules if they are damaged or fail, depending on the installation.